Abstract:

Development of next-generation power devices is needed for energy saving in a low carbon society. Diamond is a potentially important power device material due to its excellent physical and electronic properties. Here we have developed a non-plasma high-speed anisotropic etching process using a thermochemical reaction between nickel and diamond in high-temperature water vapor. This technology is expected to contribute to fabrication of diamond devices of excellent performance with highly reduced transmission loss and high-voltage endurance.

[Background]

World energy consumption has been increasing year by year, and a global-scale energy shortage is of great concern. Because of this reason, it is important to use the energy (electricity) produced by power generation even more efficiently, the key to which is the development of power devices*1) that control the electric power. The present mainstream Si power devices have been highly developed but their performance is thought to be close to maximum, which means that further development becomes very difficult. Thus, much attention has recently been paid to other materials possessing better physical properties than Si, such as SiC, GaN, Ga2O3 (gallium oxide) and diamond, i.e. wide-bandgap semiconductors*2). Among these, diamond shows not only the highest insulation breakdown voltage*3) and carrier mobility*4) but also larger thermal conductivity than any other material. These are big advantages in realizing power devices with properties of high-voltage endurance, reduced transmission loss, high-speed and miniaturization. Diamond is, therefore, regarded as an ultimate material for power devices with great promise. On the other hand, since diamond possesses extreme hardness and chemical stability, it is not an easy task to fabricate device structures by etching. Although current fabrication technology of diamond power devices uses plasma process*5), not only is the etching rate low but diamond proximal to the etching site is damaged due to the plasma, which deteriorates device performances. Thus, it was desired to develop a non-plasma process that enables diamond etching at a high-rate. In this study, by focusing on the solid-solution reaction*6) of carbon into nickel, we have aimed to develop new diamond etching process.

[Results]

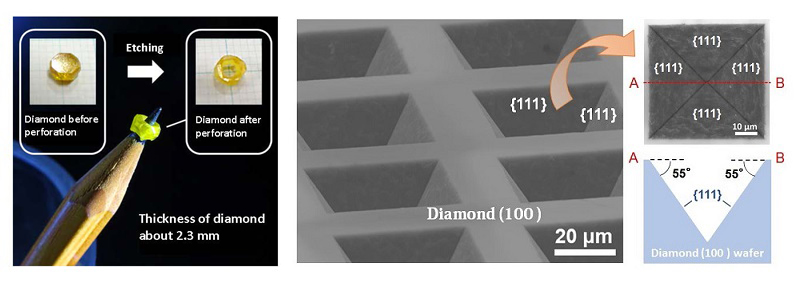

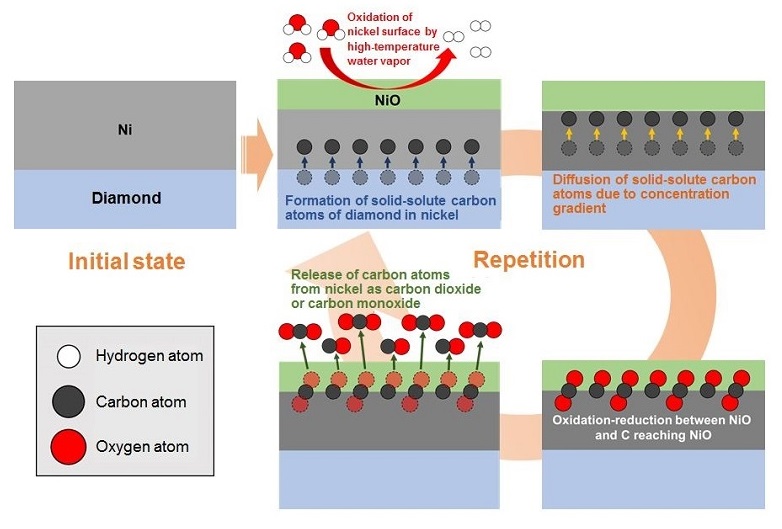

The present study was conducted as a collaborative effort of researchers from the National Institute of Advanced Industrial Science and Technology and researchers from Kanazawa University including doctor-course graduate student Masatsugu NAGAI and Associate Professor Norio TOKUDA. By employing continuous solid-solution reaction of diamond carbon with nickel in high-temperature (1000 °C) water vapor, an anisotropic diamond etching process*7) has been realized at the highest rate (approximately 8.7 μm/min) reported so far (Figure 1). The high-temperature water vapor oxidizes the nickel surface and the solid-solute carbon atoms are converted into carbon dioxide or carbon monoxide by an oxidation-reduction reaction with nickel oxide. Carbon dioxide and carbon monoxide are released from the reaction system, which prevents saturation of carbon atoms in nickel and enables continuous diamond etching at a high rate (Figure 2). In addition, high-temperature water vapor, unlike oxygen, does not react with diamond directly, so that selective etching of diamond in direct contact with nickel is now possible. Moreover, since plasma is not used, this technology does not bring about the plasma damage that deteriorates device performance.

[Future prospects]

It is expected that by using the technology developed in this study, diamond power devices with vertical trench*8) gate structures can be fabricated, which should show characteristics of highly reduced transmission loss and high-voltage endurance. In addition, this technology is expected to be applicable not only to fabrication of device structures but also to manufacturing processes like diamond flattering and cutting.

Figure 1

Left: A single crystal diamond with a hole that is perforated by the high-rate etching technique.

Center: Single crystal diamond wafer with regular trench structures produced by the anisotropic etching technique.

Right: Top view of such a trench structure and a schematic image of its cross-section.

Figure 2. Diamond etching mechanism by thermochemical reaction of nickel and diamond in high temperature water vapor.

[Glossary]

*1) Power device

A power device is a semiconductor device, a component of an inverter and a conductor, integrated in a variety of electric and electronic products such as power transmission systems, production facilities, transportation equipment and household electric appliances.

*2) Wide-bandgap semiconductor

Wide-bandgap semiconductors consist of semiconductor materials that have a larger bandgap than Si (1.1 eV).

*3) Breakdown voltage of an insulator

The breakdown voltage of an insulator is the minimum voltage that causes a portion of an insulator to become electrically conductive.

*4) Carrier mobility

Carrier mobility characterizes how quickly a carrier (an electron and a hole: a carrier contributes to electric current) can move through a solid.

*5) Plasma process

Plasma process is a plasma-based material processing technology. Plasma is a state of gaseous molecules that become ionized gas consisting of positively-charged ions and electrons by ionization. Materials that are difficult to etch by chemical reactions can be a target of etching with accelerated ions and radicals in plasma.

*6) Solid-solution reaction of carbon.

Solid-solution reaction of carbon is a reaction of carbon becoming a solute in a metal solid. The metal solid keeps its original crystal structure even with solid-solute carbon. The amount of carbon becoming a solute has a limit, which is referred to as the solid solubility limit.

*7) Anisotropic etching

Anisotropic etching is etching (processing method to obtain target shape by removing unnecessary parts chemically or, alternatively, physically via ion collision) where the etching rate in one direction is different from those in other directions. One method uses the difference in etching rate depending on the crystal faces while the other uses an accelerated ion beam in a vertical direction in plasma. By contrast, isotropic etching is etching where the etching rates are the same in any direction.

*8) Trench

A trench is a gutter formed on a wafer surface.

Article

Anisotropic diamond etching through thermochemical reaction between Ni and diamond in high-temperature water vapour

Journal: Scientific Reports

Authors: Masatsugu Nagai, Kazuhiro Nakanishi, Hiraku Takahashi, Hiromitsu Kato, Toshiharu Makino, Satoshi Yamasaki, Tsubasa Matsumoto, Takao Inokuma, Norio Tokuda

Doi: 10.1038/s41598-018-25193-2

Funders

Japan Society for Promotion of Sciences KAKENHI JP17H02786; Kanazawa University SAKIGAKE Project.

PAGE TOP

PAGE TOP